roughing end mill feeds and speeds

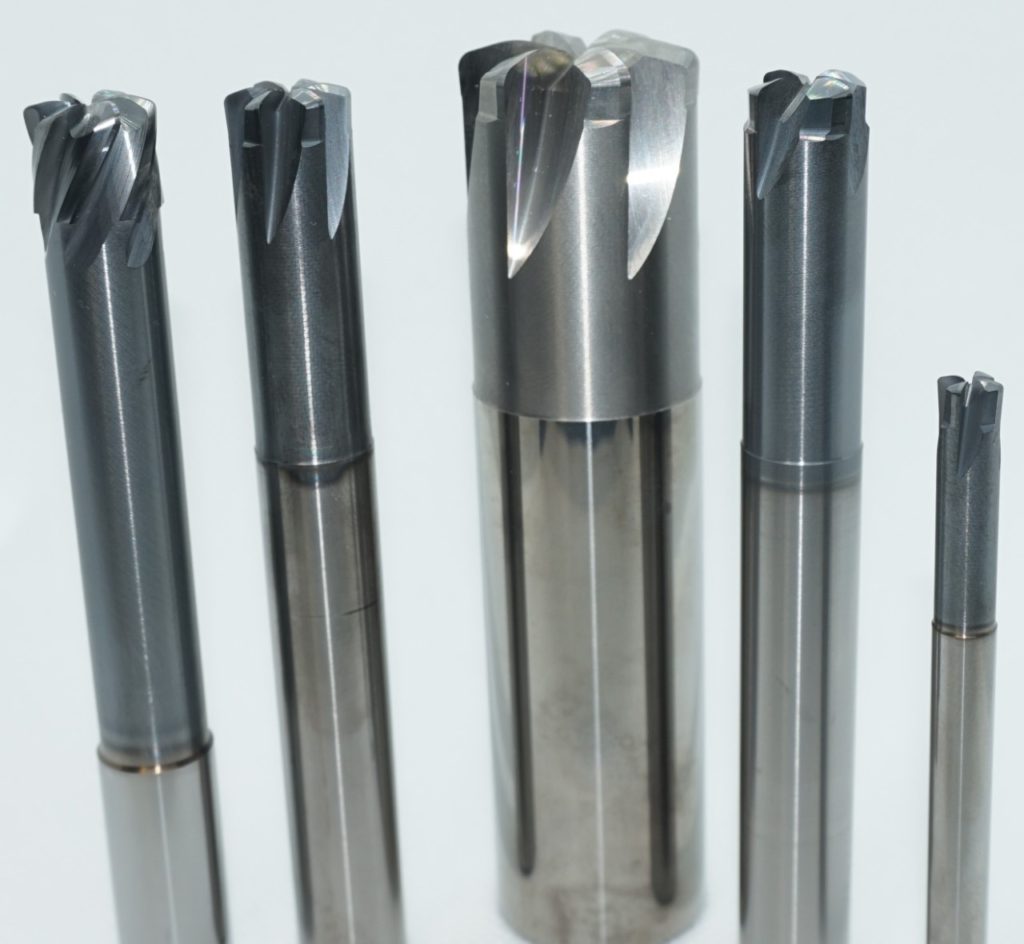

Steel Hard Milling. The specialized five flute.

8 Ways You Re Killing Your End Mill In The Loupe

Tapered end mill usage can be tricky if the proper settings are not adhered to.

. This means a 050-inch end mill will be engaged 0025. If you run your tool with too slow of a feed. Recommended cutting speed and feed for Accusize Industrial end mills 6800 series M42 HSS 8 Cobalt Finishing CNC end mill 4 flute TiALN Coated 1002 1102 and.

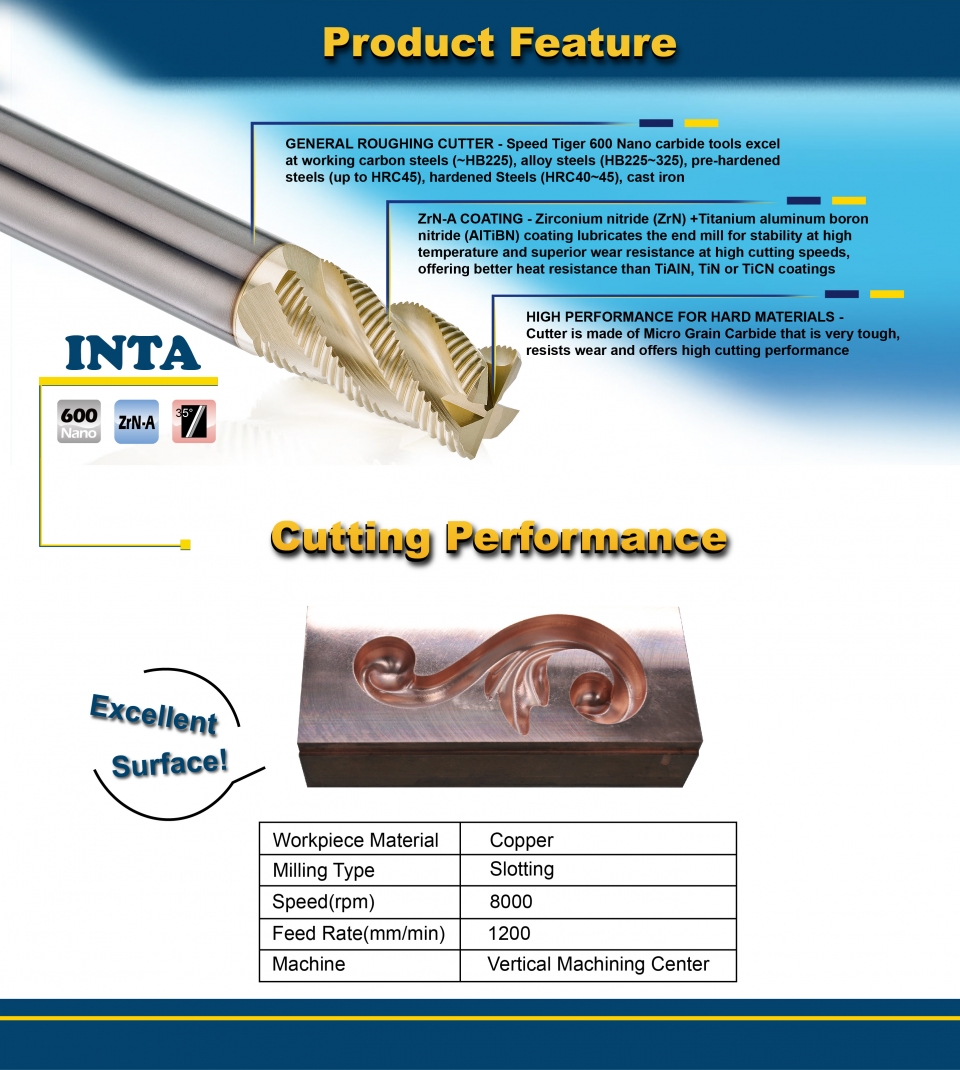

Speed Tiger Precision Technology Co Ltd. 50 - 70Rc Steel. Was founded in 1998.

V7 Stub Inox for Steel. Calculations use the desired tool diameter number of teeth cutting speed and cutting feed which should be chosen based on the specific cutting conditions including the workpiece. End Mill Speed and Feed Calculator - Martin Chick Associates Contact End Mill Speed Feed Calculator Tool Dia.

Likewise we are here to assist you in determining the correct feeds and speeds starting points based on roughing end mills or finishing end mills you are using. Another critical aspect of speeds and feeds the best feed rate for a job varies considerably by tool type and workpiece material. The new Z-Carb HPR Five Flute Roughing End Mills are ideal for achieving high metal removal rates MRR and a finish of 80 RMS or better on most materials.

Smooth Chatter Free High Speed Roughing. Increase speed by 25-50 TAIN Coated End Mills. When using long and extra-long end mills.

169 speeds and feeds chart 205 speeds and feeds chart 206 speeds and feeds chart 207 speeds and feeds chart 208 speeds and feeds chart 217 speeds and feeds chart 219 speeds and. Our G-Wizard Feeds and Speeds Calculator has special features to help with plunge milling. Radial Side Depth of Cut This will adjust the feedrate if less than the.

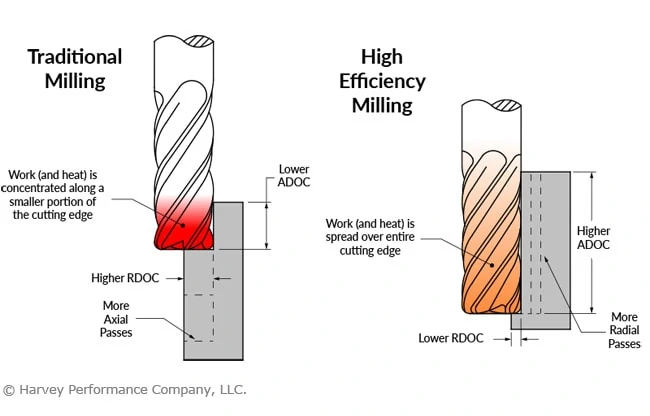

All speed and feed data are suggested starting points. SFM FPT For Material 2. For high-speed roughing width of cut is usually set at somewhere between 5 and 10 percent of the cutting tool diameter.

TiN Coated End Mills. Please contact our very. 8096 118th Avenue North Largo FL 33773 630-964-5030 Email.

They may be increased or decreased depending on machine condition depth of cut finish required coolant etc. Increase speed by 50-75. It is not only the leading carbide end mill manufacturer but also the largest cutting tools manufacturer that combined milling.

Increase speed by 25 TiCN Coated End Mills. Helix - Primarily designed for high temperature alloy machining in materials s. Feed should be 05 X Suggested Value.

Suppose we are handed. V7 Stub Inox for Stainless Steel. Diameter Tolerance is 0005-0005 Solid Carbide end Mills during use roughing the for.

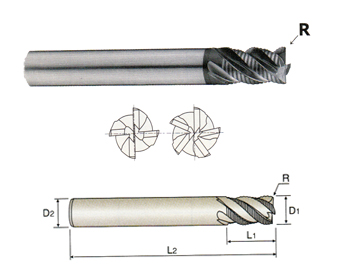

Profiling Cutting Depth Recommendations and Adjustments Axial Depth of Cut AD Axial Depth of Cut 15 X Tool. Please follow these endmill usage charts as closely as possible. SFM 08 X Highest Speed Range.

Lets work through an example that shows the strengths of plunge milling.

Guide How To Select The Best Cnc End Mill

Speeds And Feeds Beginner Guide With Table Mellowpine

Guide How To Select The Best Cnc End Mill

High Speed Video Power Rounds Solid Carbide End Mill Roughing 4140 Steel Youtube

4 6 Flute High Feed End Mills Epic Tool

Carbide End Mill Feeds And Speeds Explained Sctools

Plastic Milling Guidelines Hss Roughing Cuts Curbell Plastics

Yg 1 Best Value In The World Of Cutting Tools

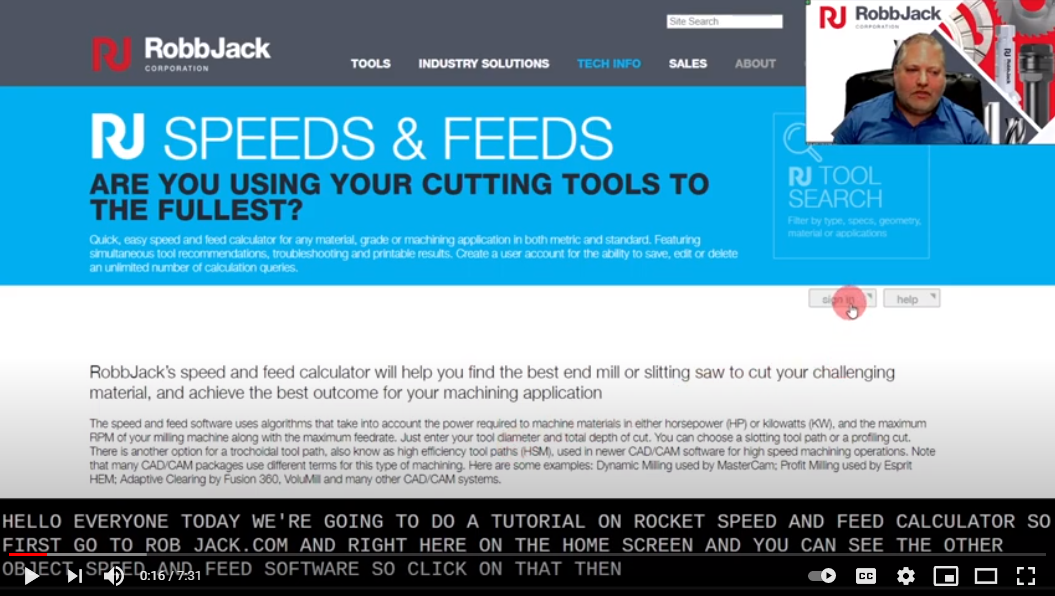

Robbjack S Speed And Feed Calculator Will Help You Find The Best End Mill Or Slitting Saw To Cut Your Challenging Material And Achieve The Best Outcome For Your Machining Application

Recommended Cutting Conditions Square Technical Information Tools For Machine Processing Tools Misumi Vona Comprehensive Web Catalog For Misumi

Speed Feed Recs Melin Tool Company

Recommended Cutting Conditions Roughing Technical Information Tools For Machine Processing Tools Misumi Vona Comprehensive Web Catalog For Misumi

Specification High Performance End Mill

Speeds And Feeds Chart For Roughing With Variable Pitch And Helix Endmills Machine Tool Recyclers

Speed Tiger Iaue Carbide Square End Mill For Aluminum Applications High Feed U Type Design For Roughing And Finishing 3 Flute Iaue1 2 3 Made In Taiwan 1 Piece 1 2

Brief High Feed Contour Ramping Vs High Efficiency Milling Dapra Corporation